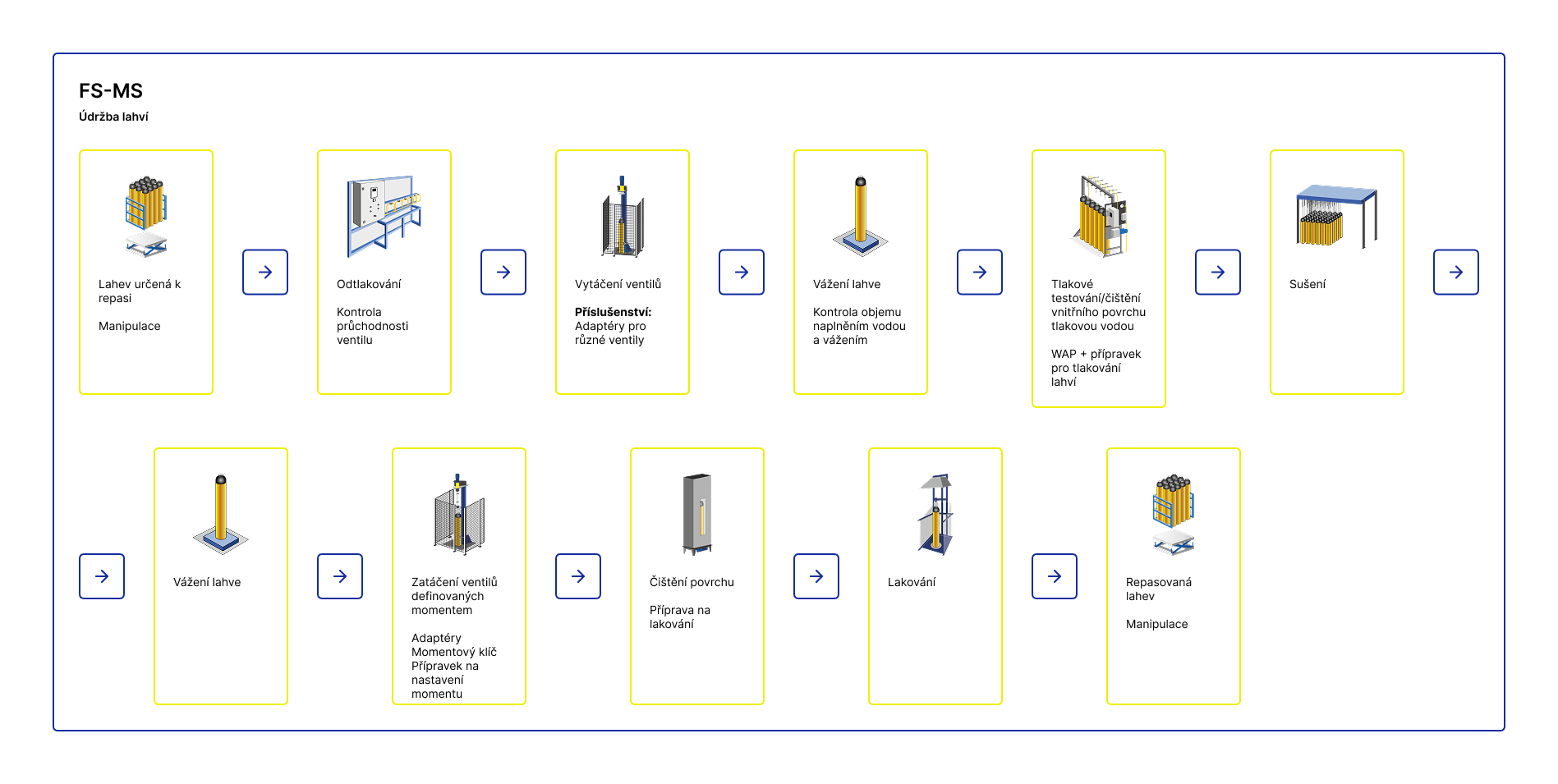

Bottle maintenance

We supply complete technological equipment for service and filling stations for pressure cylinders. Our equipment is designed for safe, efficient, and fully automated maintenance, inspection, and preparation of cylinders for further operation. We offer solutions for industrial, firefighting, medical, and defense applications.

We supply

- Handling equipment – ergonomic and safe systems for moving, rotating, and clamping pressure cylinders.

- Depressurization equipment – controlled systems for safely releasing residual pressure and venting cylinders before maintenance.

- Valve unscrewing and screwing devices – universal devices for automated removal and installation of various types of valves.

- Cylinder weighing devices – precise weighing stations for checking weight before and after filling or maintenance.

- Pressure testing chambers (“pressure testers”) and internal surface cleaners – high-pressure systems for hydrostatic testing and pressure cleaning of the inside of bottles with water.

- Bottle dryers – equipment for fast and gentle drying of the interior after cleaning or testing.

- External surface cleaners – brushing or blasting technology for removing old coatings and dirt.

- Bottle painters – automated painting lines for final surface treatment and color marking.

Our standard equipment can be customized according to customer requirements.

Why our solution

Safety

robust industrial design with an emphasis on safety and long service life

Modular configuration

assembly of a complete line according to customer requirements

Standards

compliance with all relevant technical and safety standards

Service

service, operator training, and technical support, including spare parts delivery

Experience

Extensive experience in supplying the defense, firefighting, and industrial sectors